Plastic is everywhere—from your morning coffee lid to the packaging on your groceries. But what if the solution to plastic pollution isn’t in the landfill, but in seaweed, mushrooms, or even food waste?

We’re witnessing a materials revolution. 🌍✨ Scientists, entrepreneurs, and nature itself are offering a new generation of plastic alternatives that are plant-based, biodegradable, and designed for circularity:

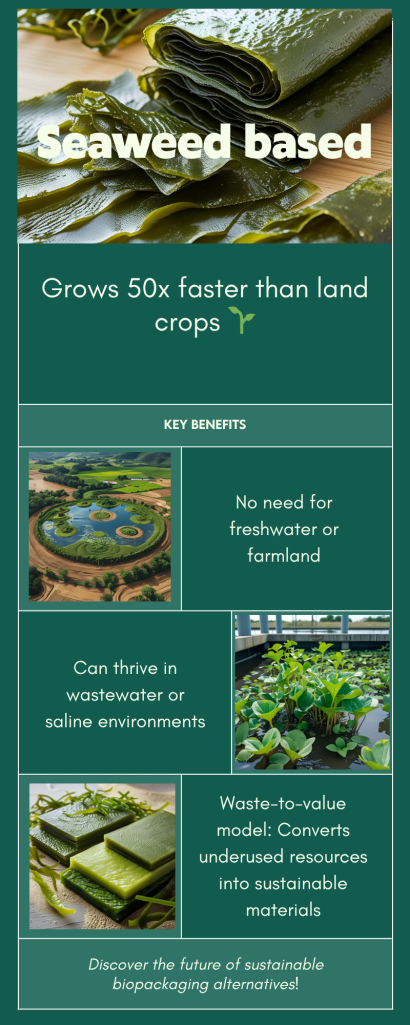

🌿 Seaweed-based

🔹 WHY

- Grows 50x faster than land crops 🌱

- No need for freshwater or farmland

- Can grow in wastewater or saline environments

- Waste-to-value model: Converts underused resources into sustainable materials

📦 Innovative Applications

- Edible drinking straws & gel pods

- Compostable takeout containers & cutlery

- Biodegradable condiment packets and detergent pods

- Breaks down in < 47 days!

🌎 Environmental & Market Impact

- Biodegradable → drastically cuts ocean plastic waste 🐠

- Lower carbon footprint than fossil-fuel plastics 🌍

⚠️ Challenges to Scale

- Technical & regulatory hurdles

- Need for policy support, R&D investment, and market incentives for mainstream adoption

- High production costs

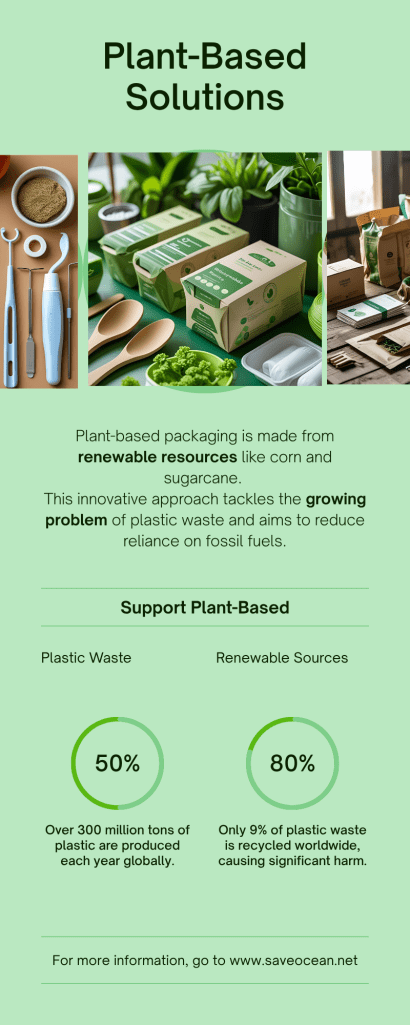

🌿Plant-based

🔹 WHY

- Derived from renewable sources (corn, sugarcane, food/agricultural waste) 🌎

- Tackle the growing problem of plastic waste

- Aim: reduce dependence on fossil-based plastics ♻️

- Range: Non-biodegradable ➡️ Fully biodegradable

- Moving toward circular, low-waste systems 🔄

📦 Innovative Applications

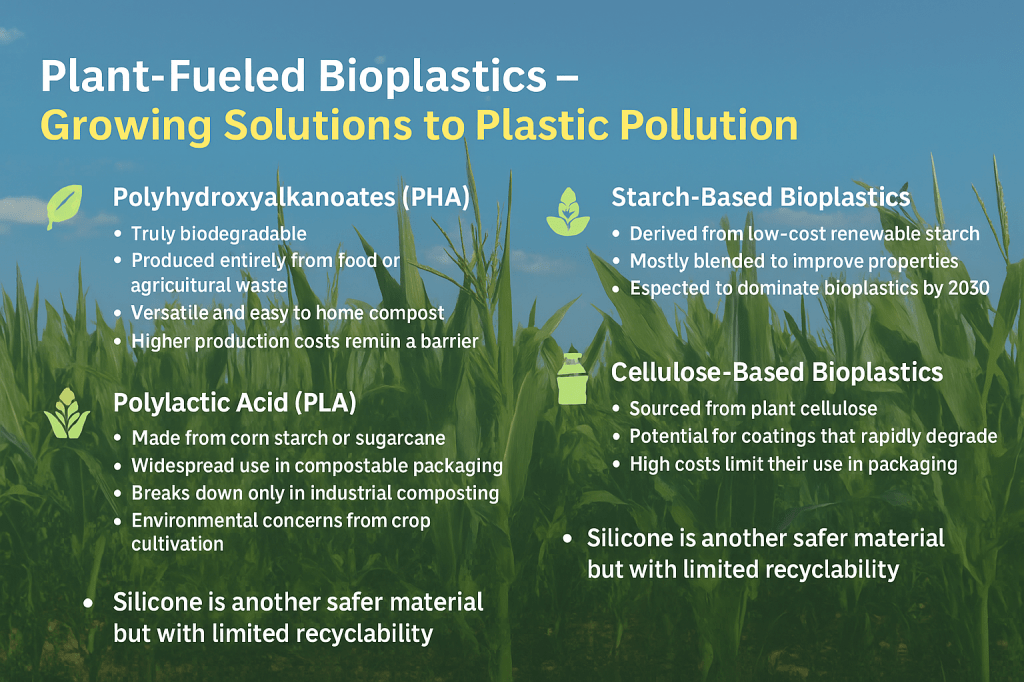

- PHA: Produced from food/agricultural waste via bacterial fermentation.

Used in: food packaging, medical products - PLA: Derived from fermented corn starch or sugarcane. Used in: compostable packaging, disposable utensils, medical devices, textiles, and prototyping

- Starch–Based: Bioplastics Sourced from corn, potato, sugar can. Projected to lead the bioplastics market by 2030

- Silicone: Derived from silica (sand/quartz), not fossil fuels. Used in: medical implants and kitchenware.

🌎 Environmental & Market Impact

- PHA: Biodegradable, non-toxic, compostable at home and in marine environments 🐠, but slow in landfills and lacks recycling systems.

- PLA: Bio-based but only degrades in industrial composters; crop-based feedstock raises food security concerns

- Starch-Based: Reduces CO₂ emissions by 30–70%, uses plant waste, but cost remains a barrier.

- Silicone: Does not shed microplastics; however, limited recyclability

⚠️ Challenges to Scale

- Material Limitations

- Blending & Compatibility Issues

- High production costs often cost 2-5× more than petroleum-based plastics.

- Sustainable sources for consistent supply of biomass.

- Recycling compatibility and limited industrial composting

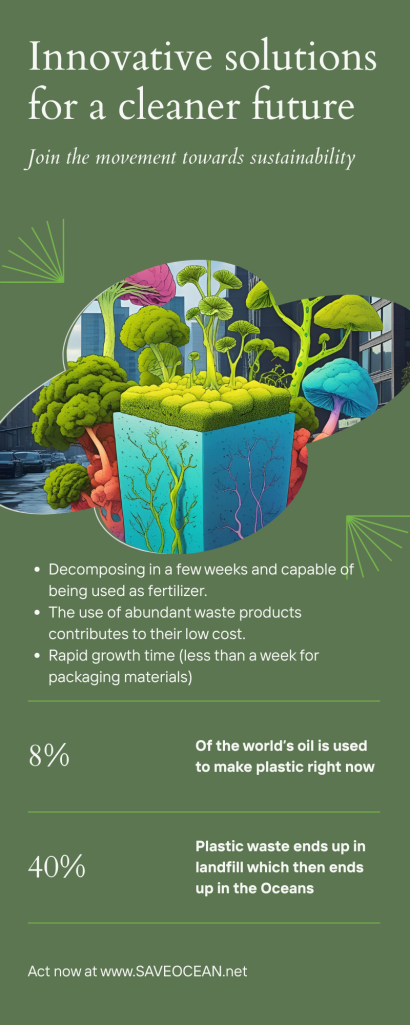

Mycelium based

🔹 WHY

- Acts as a natural biological adhesive, binding together lignocellulosic by-products like wood, straw, hemp, and wheat waste

- Leverages natural biological processes to create materials

📦 Innovative Applications

- 11 distinct application areas, with 5 already commercialized

- Key uses include packaging (notably replacing polystyrene foam), design, building, fashion, and cosmetics

🌎 Environmental & Market Impact

- Decomposing in a few weeks and capable of being used as fertilizer.

- The use of abundant waste products contributes to their low cost.

- rapid growth time (less than a week for packaging materials)

Seaweed commercial pioneers

| Company | Material type | Products |

| Sway | Cultivated macroalgae and seaweed extracts | Thin-film, seaweed-based packaging |

| Notpla | Specific type of seaweed called Porphyra Yezonesis, a red seaweed | Ooho and Notpla Seaweed Paper. Compostable seaweed packaging. dissolvable, microplastic-free sachets |

| Sea6Energy | Seaweed cultivation (SeaCombine) | Bioplastics, films, coatings, and straws |

| Algopack | Brown seaweeds like Sargassum and Laminaria digitata | Bioplastic granules |

| B’Zeos | Kelp-derived | Home-compostable films, straws, and paper coatings |

| Evoware | Local seaweed | Produces edible cups, sachets, wraps, straws |

| Kelpi | Brown seaweed | compostable, marine-safe seaweed packaging with high water-barrier properties |

| mujō | Fast-growing kelp alginate | fully biodegradable packaging |

Plant Based Commercial pioneers

| Company | Material Type | Feedstock | Key Achievements |

| Danimer Scientific | mcl‑PHA | Plant oils | Nodax® resin, FDA & marine-certified |

| CJ CheilJedang (PHACT®) | PHA | Renewable biomass | Large‐scale plant, marine-certified |

| Newlight Technologies | PHA (AirCarbon®) | Renewable CO₂/Greenhouse gases | Collaborations with Nike, IKEA, Dell |

| Genecis Bioindustries | PHBVs | Food/agricultural waste | Thermo-resistant packaging, 3D printing |

| Mango Materials | PHA | Methane biogas | Circular feedstock, cost-efficient production |

| NatureWorks (Ingeo™ PLA) | PLA | Corn sugar | Global production capacity, industrial compostable |

| TotalEnergies Corbion | PLA (Luminy®) | Biomass | 75 k t/year Thailand plant |

| BASF | PLA/PBAT blends | Renewable & fossil feedstocks | eco-flex®, eco-vio® blends |

| Novamont (Mater-Bi®) | Starch/PHA blends | Agricultural feedstock | Compostable bags, strong R&D heritage |

| Biome Bioplastics | PLA/PHA | Renewable sources | Packaging & durable applications |

Comparative Strengths & Weaknesses

- Biodegradability:

- Rapid: Seaweed-based, PHA, mycelium.

- Industrial-only: PLA, PBAT.

- Performance Trade-offs:

🌱 Environmental Footprint Nuances

- Carbon Emissions:

- Bioplastics often reduce emissions, but not universally.

- Feedstock growth can offset CO₂ emissions.

- Land & Water Use:

- Crop-based plastics: risk of deforestation and high water use.

- Algae: low-impact – no arable land or freshwater needed.

Innovation Bottlenecks

- Effectiveness of disposal depends heavily on proper infrastructure:

- Thus, policy and waste infrastructure are as critical as material innovation.

- Further material science breakthroughs are needed to:

- Improve durability + biodegradability

- Reduce cost of microbial fermentation

- Scale waste-to-bioplastic conversions (e.g., methane to PHA, cellulose to packaging

✅ Conclusion

Bioplastics and alternatives vary widely in sustainability. But here’s the catch: sustainability isn’t just about materials. It’s about systems—how we produce, use, and dispose of what we make. A compostable fork is only eco-friendly if it actually gets composted.

✅ The future of packaging isn’t just about finding a “green plastic.”

🧠 It’s about rethinking our relationship with materials—from cradle to grave.

Let’s move beyond single-use. Let’s grow our solutions. 🌱♻️

Leave a comment